Process Safety

Improve Operations and Mitigate Risk

Do you know if your process operates at an acceptable risk?

这在很大程度上取决于您的流程操作和全公司范围内的安全策略和政策中内置的安全层. 识别和预防工厂中的安全风险和危害, it is vital to implement and maintain process safety.

When it comes to process safety projects and hazardous operations, such as startups and shutdowns, MAVERICK Technologies brings deep domain experience, 利用行业标准和最佳实践来帮助提高设施产量, improve operational quality and efficiency, ensure safety and enhance regulatory compliance.

为了改进操作和预防事故,MAVERICK主题专家采用以下组合:

- Process control knowledge

- Industrial automation depth

- Safety Instrumented System (SIS) expertise

对我们来说,这不仅仅是技术和流程的问题,也是工厂员工的问题. 我们确保设施人员拥有完成各自工作所需的正确工具和技术. 我们还帮助他们更好地了解他们在更广泛的过程安全图景中的角色,并确保持续改进措施到位以维持运营.

The MAVERICK Approach

MAVERICK明白你必须预先对你的运营做出决定, identify risks and how much risk you will tolerate.

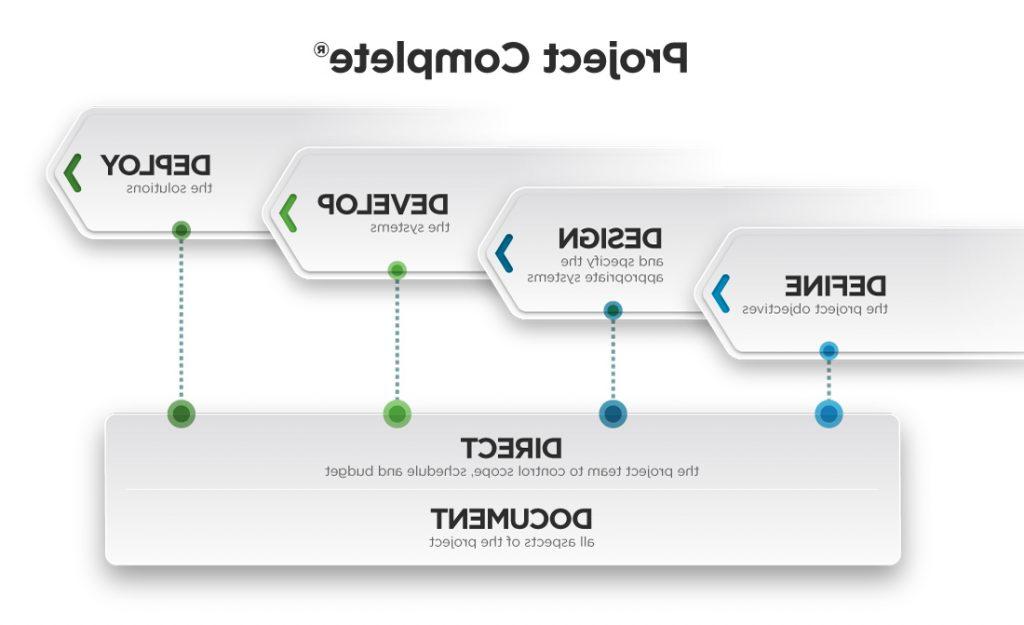

项目管理是过程安全项目成功的最重要因素之一. MAVERICK employs the Project Complete® approach to project management, 我们的项目经理在过程安全项目生命周期的每个阶段执行什么:定义, design, develop, deploy, direct, document.

MAVERICK专家可以帮助您制定功能规格、计划和执行.

-

1

Define

-

2

Design

-

3

Develop

-

4

Deploy

Hazard Identification (HAZOP)

通常称为过程危害分析(PHA)或HAZOP. It is the step where a facility identifies hazardous scenarios. At a minimum, it requires a trained facilitator, a subject-matter expert from process engineering, and an operations representative. 通常这个团队会更大,包括内部和外部的操作人员/主管, as well as other engineering disciplines such as process control, mechanical and electrical.

Layer of Protection Analysis (LOPA)

LOPA is one way to perform process hazard analysis (PHA). 它包括分析安全保护措施实施后剩余的可容忍风险.

Tolerable Risk

可容忍风险是公司用来确定其相对安全策略的基准. 大多数大型运营商都将这些决策量化在表格和图表中. If you are starting to implement SIS in your facility, this is a critical step, and we can help with experienced facilitators and experts.

Probability of Failure on Demand (PFD) Calculations

您如何知道您一直依赖的联锁将满足SIL2的标准? You must do the math. We can help guide you through this process.

Installation Details

When installing any new instrument, but especially when implementing a new SIS protection layer, the instrument must be installed right. 我们经验丰富的设计师团队可以为您的下一个项目提供详细的仪器安装细节.

Software Requirement Specification (SRS) Generation

SRS是安全标准的要求,它规定了SIL功能的所有细节. 它包括证明保护功能将满足预期用途的文件. Whether you have your own template, or want us to use ours, 我们有完成说明书所需的学科范围.

Certified vs Proven in Use

For an instrument to be used in SIL service, 它应该有制造商的SIL认证,或者操作员可以自我认证它在使用中被证明. 如果您决定进行自我认证,我们可以帮助您做出决定并设置您需要的记录保存.

SIL Calculations

仅仅因为SIL3变送器连接到SIL3 PLC并关闭SIL3阀, the function is not SIL certified. It only means that the components are SIL3 capable. SIL功能必须满足其所需的按需故障概率(PFD). 确定按需故障的概率(系统在被调用时工作的几率), you must do the math. 我们有使用许多商业上可用的软件包分析SIL级别的经验.

Proof Test Procedures

确定SIL功能的一部分是测试它的频率,以试图找到未检测到的错误(例如.e., it broke, but you can’t tell). This test is called a proof test. 我们有证明测试仪器,阀门,电机接触器和逻辑求解器的书面程序.

Validation Procedures

在将SIL功能视为“在使用”之前,必须对其进行适当的测试和验证. We have written validation procedures for many of our customers, and our field technicians have executed even more.

HMI and Control Programming

In addition to safety system programming, 一些lopa认证的保护在基本过程控制系统(BPCS)上以联锁和警报的形式实现。. MAVERICK拥有在工业应用中几乎所有DCS和PLC系统上实施BPCS保护的经验.

SIF Programming

When programming a safety system, 理解逻辑求解器的安全手册和最佳实践非常重要. With dedicated technology leaders, MAVERICK对我们支持的所有平台的质量都有承诺.

Code Verification and Assessment

For a safety system, good programming practices isn’t enough. The control code must be tested to prove functionality, 而且必须进行评估,以证明安全手册的规定得到了遵守.

Commissioning and Field Verification

Once installed in the field, 验证试验证明,该安全功能在需要时能够正常工作. MAVERICK的现场技术人员在许多行业都有执行SIS验证的经验.

MAVERICK Can Help:

- 启动或更新您的过程安全管理(PSM)计划和指导方针.

- 进行过程危害分析(PHA)/危害和可操作性(HAZOP)研究或其他审核,以确定任何与安全相关的问题,或识别可能导致事故或问题的情况或潜在系统故障.

- 提供具有不同背景的专家,他们可以提供有关工厂关键系统的见解和信息.

- 审查PHA/HAZOP讨论的结论,并确保其正确应用.

- 为关键事件建立警报,并了解每个警报所需的响应.

- 促进osha规定的培训,使操作人员了解标准操作程序的所有变化,并能识别潜在的危险.